Overview

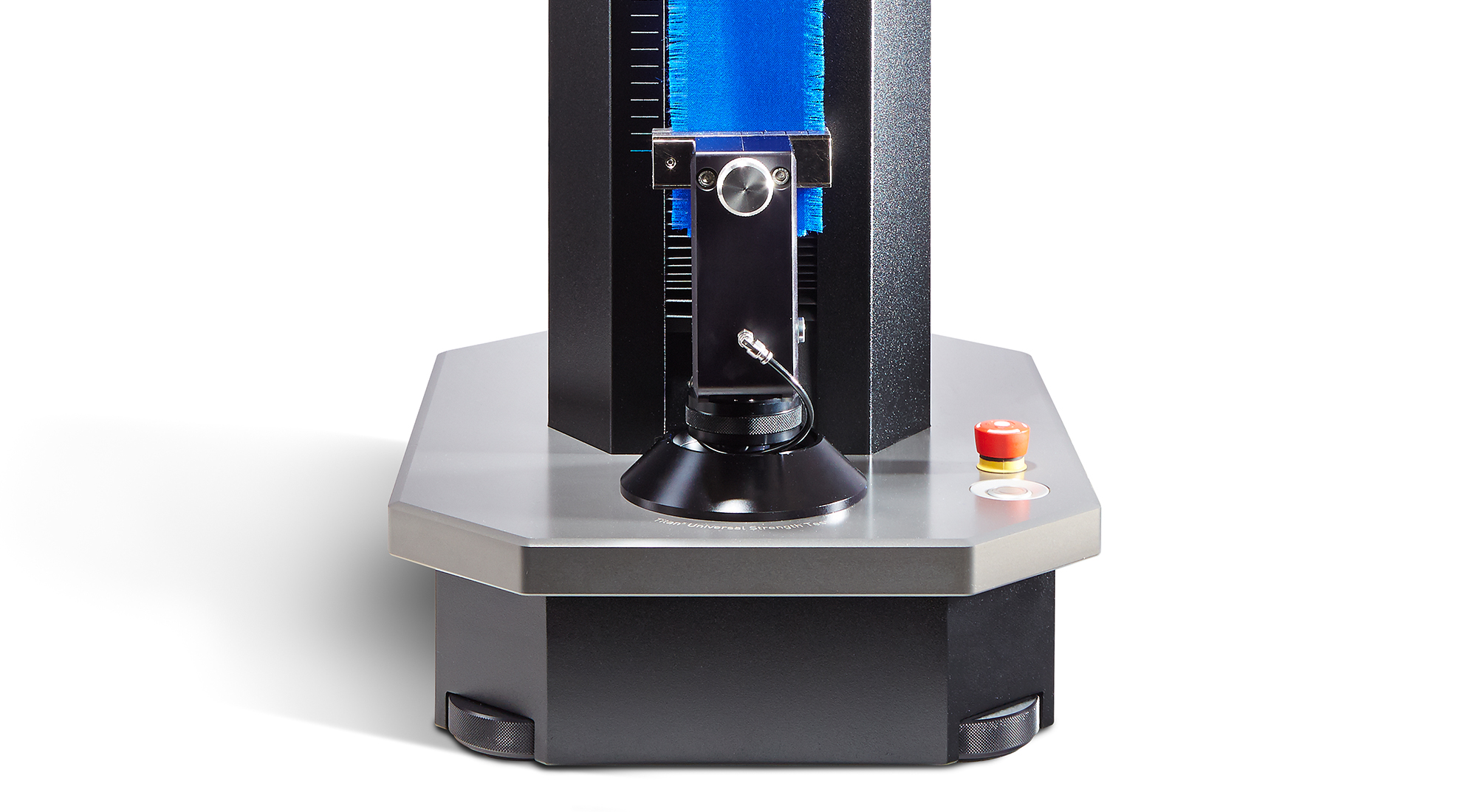

Universal Testing Machine with TestWise™ software, available in 5 kN, 10 kN and 25 kN capacity models. A universal strength tester suitable for testing a diverse range of applications - including apparel, nonwovens, and other non-textile materials.

New Titan 10 and Titan 25 models are now available - find out more on the recent product launch.

Brochure(s)

Got a question about this solution?

Get in touch and speak to one of our Technical Sales Engineers now...

Speak to an expert

Features

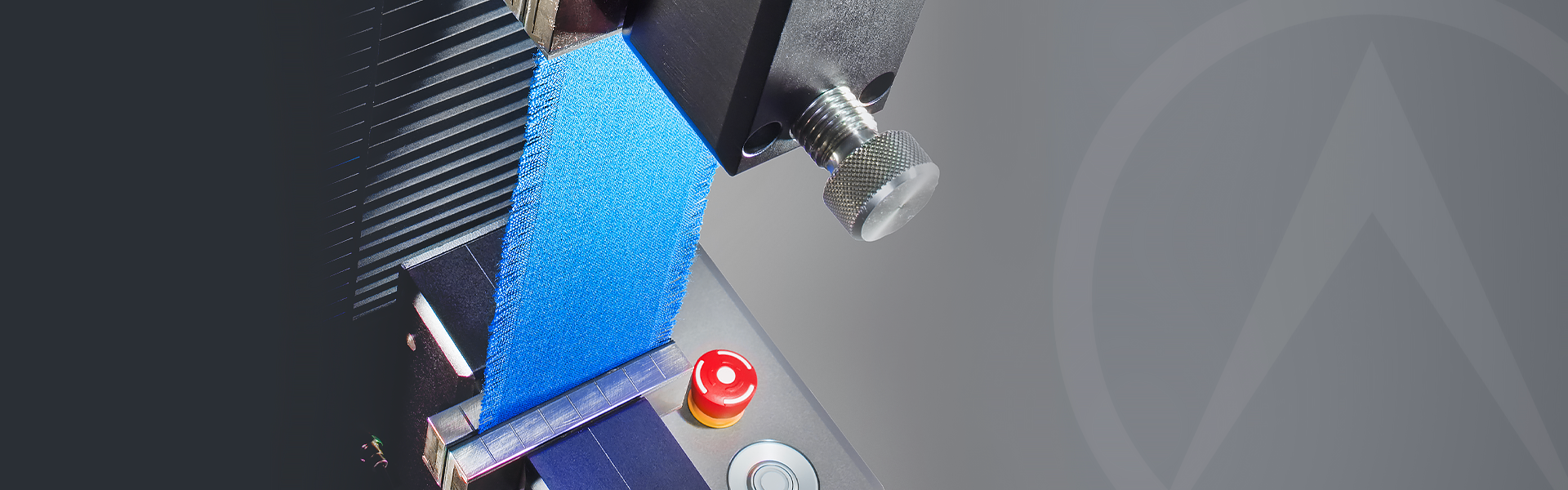

Interchangeable Tools

The load cells and the extensive range of tool-free specimen grips are interchangeable between Titan 5, Titan 10 and Titan 25.

Labs can perform a wider range of tests and comply with more Standards on a wider range of test types.

Hand-held Controller

A hand-held controller for improved manual testing, useful when gripping specimens of variable or irregular size.

TestWise™

Advanced software made simple, for faster, smarter testing. With annual software upgrades or customers with a TechSmart™ Titan agreement.

Features include pre-loaded test parameters, filters and favourites to find standards and export to PDF and Excel. Minimal training required.

Standards

Over 500 pre-loaded standards and retailer test methods, which the user can customise.

Additional information

Titan is a universal testing machine for tensile and compression testing, which has been designed for accuracy, efficiency and ease of use. Tensile testing is used to understand and determine the maximum load that a material can withstand. The sample is subjected to a controlled tension until failure. Examples of properties that can be measured with Titan include, ultimate tensile strength, breaking strength, maximum elongation and reduction in area.

Titan can test a range of applications including:

- Yarns

- Fabrics

- Seams

- Shoes

- Ropes

- Straps

Titan10 is also a dual column instrument, meaning larger samples can be tested across a full range of tests including tension, compression, stretch and recovery, tear, peel, adhesion peel and other applications. It has a vertical test space of 1200mm and a space between columns of 460mm.

Titan has the flexibility to allow the operator to control the instrument manually through the hand-held controller, the SMART button or on screen. The hand-held controller enables ‘at instrument’ control for effortless sample loading, this is especially useful when positioning and gripping specimens of variable or irregular size.

Material / End use

Technical Specification

Specifications are provided as a guideline only and are subject to change.

| Conditioned atmosphere recommended | Yes |

|---|---|

| Positioning | Bench standing |

| Space requirements | |

| Titan5 |

Depth 56.8cm Width 40.0cm Height 133.9cm |

| Approximate net weight | |

| Titan5 | 82kg |

| Power | Single phase Yes |

| Rating per phase (A) 1.0A | |

| Watts 60 | |

| Compressed air | Pressure 7-10 bar, 700-1000 kPas, 100-145 psi |

| Minimum flow 17 litres per minute | |

| Filtration 5 microns or better to remove oil and moisture | |

| Air Regulator Not required, built into Titan | |

| Personal Computer (PC) - Minimum Specification | OS Windows® 8, Windows® 7, Windows® 10 |

| Not compatible with Windows® XP or Windows® Vista | |

| Microsoft.NET 4.0 Framework is required (included on disc) | |

| HDD Minimum 250GB | |

| Ports At least 3 free USB 2.0 ports if using the Hand Held Controller | |

| Read our Frequently Asked Questions and download the Operators Guide for Titan Universal Testing Machine | KnowledgeHub |