Overview

Quick-drying is an important attribute of textiles worn next to the skin, during sporting activities where the skin is likely to perspire. ProDry replicates the conditions to verify the quick-drying fabrics are performing effectively.

Brochure(s)

Got a question about this solution?

Get in touch and speak to one of our Technical Sales Engineers now...

Speak to an expert

ProDry tests to AATCC Test Method 201 Drying Rate of Fabrics: Heated Plate Method, and can be configured to accommodate bespoke test methods also.

Features

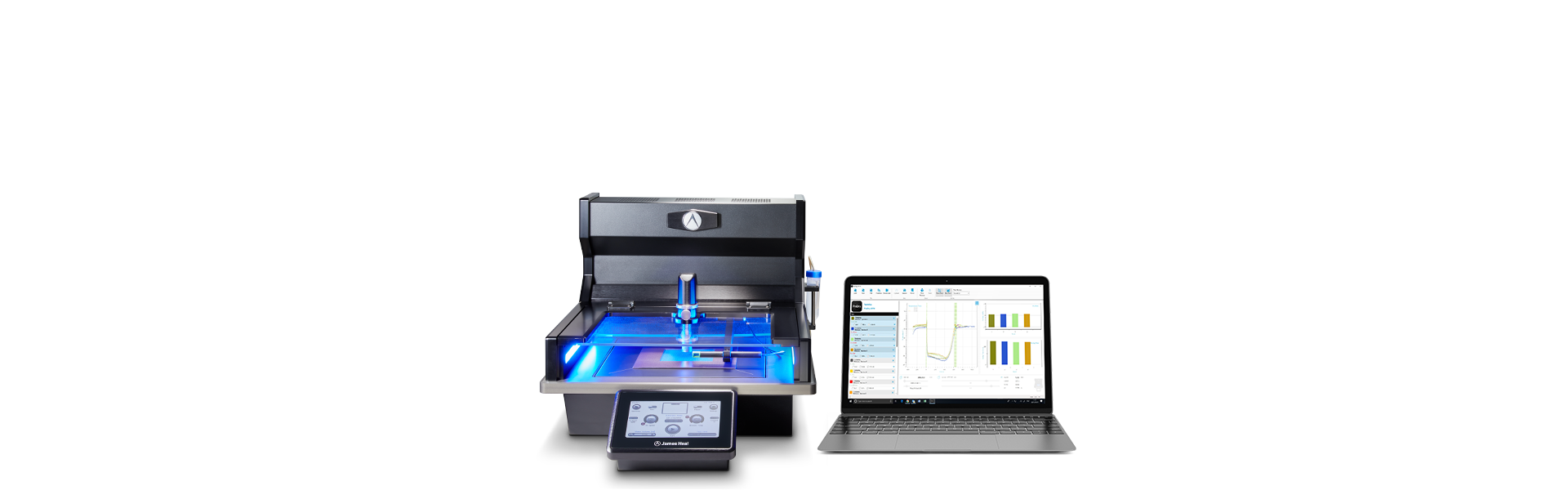

Advanced TestWise Touch

Our most advanced version of TestWise Touch can automatically set up the parameters of the test, find the end point and shows a real time presentation of results. Results can be presented in a table or graph, which has pinch and zoom functionality for increased detail.

Consistent Airflow

Multiple fans, an air filter and positioning of air flow sensors provide consistent air flow which is measured and controlled by an integrated airflow sensor.

Option to Increase Data Points

Our internal testing found that increasing the number of data points used to calculate the test end time improved the accuracy and consistency of the results. Additional data points can be added into the graph once the test is complete.

Adjustable Temperature Sensor

An adjustable temperature sensor ensures that ProDry complies with the AATCC standard regardless of how thick the fabric tested is. Setting gauges are provided for quick set up.

About the Test Method

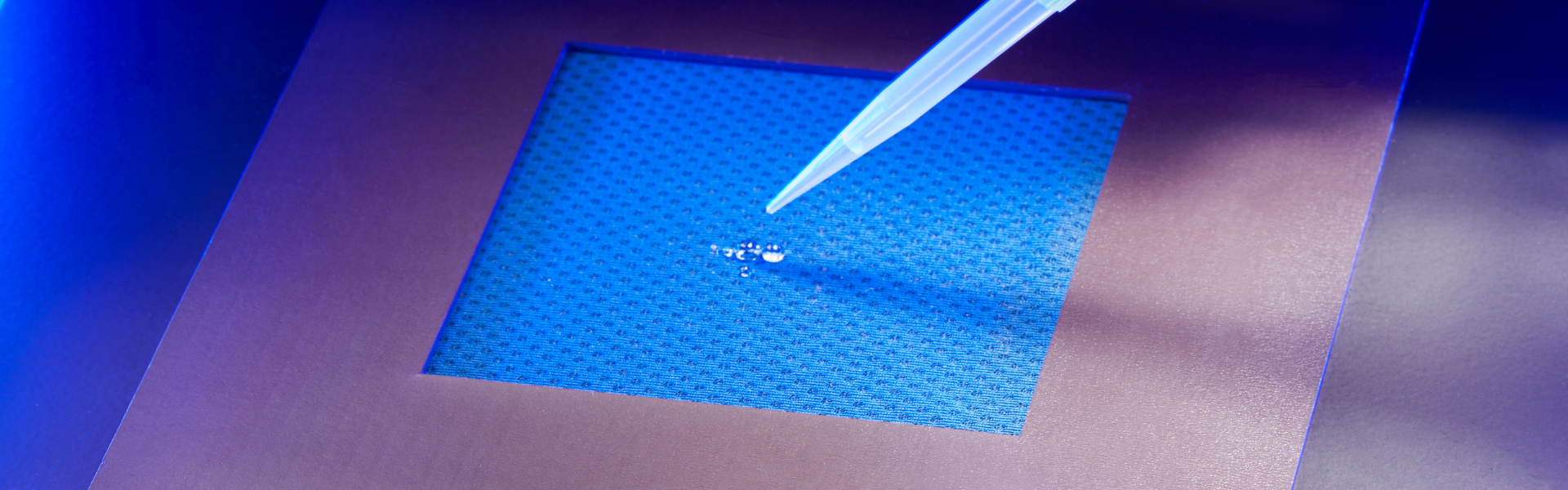

The ProDry is capable of measuring the rate at which a textile specimen dries after being exposed to water. The specimen is placed on a heated plate, which is maintained at 37°C to simulate the temperature at which human skin begins to perspire. Water is dosed on to the heated plate underneath the specimen to simulate perspiration.

The temperature drops when the specimen is wet and as the specimen dries, the temperature gradually increases. James Heal’s TestWise software records this change in temperature and automatically calculates the drying time and rate of the tested specimen.

Material / End use

Technical Specification

Specifications are provided as a guideline only and are subject to change.

| Conditioned atmosphere recommended | Yes |

|---|---|

| Positioning | Bench standing |

| Space requirements | |

| ProDry |

Height 447.5mm Width 520mm Depth 622.84mm |

| Approximate net weight | 48kg |

| Personal Computer (PC) - Minimum Specification |

OS Windows® 8, Windows® 7, Windows® 10 Not compatible with Windows® XP or Windows® Vista Microsoft.NET 4.0 Framework is required (included on disc) HDD Minimum 250GB Ports At least 1 free USB 2.0 port if using USB version of software |

| Water Supply | Each test uses 0.2ml of de-ionised water. ProDry is supplied with a test tube to complete all tests This Instrument does not need to be connected to mains water supply |