We repeated our Fundamentals of Light Fastness testing webinar, so have move informative and interesting Questions & Answers to share with you.

The key topics covered in part 2 were:

- Reducing test duration

- Checking radiation during testing

- PET Film or Plastic?

- Material thickness limitations

- Blue wool exposure under different light sources

- Test duration vs real life

- Difference in grey scales and blue wools

- Samples on a card

- Learning more about colour fastness

- AATCC 16.3 and ISO 105 B02

- Standards for preparatory methods

- Standard for towels and swimwear

- Pile/Nap surfaces

- Lifespan of Blue Wools and Lamps

- Using Grade 3 water

- The impact of climate change on light fastness

- Alternates to Xenon Arc

- Atmospheric temperature and humidity

- Measuring blue wool between cycles

- Aluminium foils as sample masks

- AATCC Blue Wool vs ISO Blue Wool

Q: The duration of the test for light fastness testing is higher compared to other physical test, can the test duration be reduced as per customer demand?

A: No, the test cannot be sped up, although the test is long it is a sped up version of ageing fabrics in real sunlight. The only way to shorted the duration of testing is if the customer wants a shorter test to a lower blue wool grade - i.e. to a BW2 rather than a BW4, but you wouldn't be testing to the full extent of the standard.

Q: How often do you recommend a check of the radiation during a Test procedure?

A: We recommend continuous checking, we've discussed that light fastness testing takes a long time, you don't want to get to the end of your test duration to find out your radiation was incorrect. The TruFade SolarSens measures the irradiance constantly.

Q: Can we use a Xenon Arc tester for PET film or plastic?

A: For James Heal's Xenon Arc tester, we would not advise testing products like PET film and plastic. The instrument has been designed to test textiles. We cannot advise on other manufacturers instruments.

Q: Are there in material thickness limitations? Specifically for Carpet testing.

A: Sample holders can accomodate samples up to a thickness of 3mm. As carpets are generally thicker than this, the James Heal TruFade cannot test carpets.

Q: Does the Blue-wool keep the same relative performance when exposure under different light sources? For example, outdoor light vs. indoor light with UV filter window glass, or Xenon lamp chamber test vs. LED lamp test chamber?

A: No, the fading times are different. The approximate timing examples given in the presentation relate to ISO 105 B02 A1 (Temperate climate) only.

Q: If I get a rating of 5 for a fabric in light fastness, what does that actually mean? We are faced with questions by customers, asking: 'So how long will this textile keep the original color?' What does the rating actually mean to the end customer?

A: This is a difficult question as the results are not related to the samples real life performance, but rather indirectly as an indication. It is then up to specifiers, such as retailers, to specify a blue wool rating to a level where the fading is acceptable, commonly where they will not get complaints. You need to know the specific test that your rating relates to that has been carried out on your fabric before attempting to establish the approximate fade time under given conditions. For example, On an ISO B02 A1 Temperate setting of (47 ± 3) °C, 40 % effective humidity & (42 ± 2) W/m2 irradiance it takes approximately 80 hours of continuous exposure for a blue wool 5 to fade to a grey scale 4.

Q: What are the differences between Grey Scales and Blue Wools in Light Fastness Tests.

A: The Grey Scale is used to grade the blue wool, then the blue wool is used to grade the specimen. Our light fastness webinar details a lot of this process, you can watch or rewatch it here.

Q: How many samples can be tested on a single mounted card, and how many samples can be testing in a single pass?

A: For ISO light fastness standards, you can include 10 x 10mm deep specimens. You can also use a combination of larger samples or just one sample. You can see a couple of layouts on the image below.

Q: I want to learn more about colour and colour fastness, where do I start?

A: The best place to begin is by contacting the local textile college and visiting libraries (local & online). Search online to see if there are any textile associations to join these can be a good source of information and some offer courses, they are also a good place to network. Linked-In is also another good source for contacts. We have educational resources on our blog, and you can also watch our range of webinars on demand for further education.

Q: Can the TruFade model perform AATCC 16.3 and ISO 105 B02 test methods? If yes, can you explain how?

A: Yes, they perform to AATCC 16.3 & ISO B02, please see brochures & the relevant standards. In the TruFade, all the standard parameters are pre-set into the machine and the required time is set by the operator and the test is begun using the start button. If you have a TruFade please see the Operator's Guide and/or contact us to arrange training.

Q: I'd like to know what standards should be used as a preparatory method for both the samples in comparison when running the tests in 1st Method and 3rd Method?

A: You are referring to methods in the standard ISO 105 B02. See Annex E.6.2 for Method 1 & E.6.4 for Method 3 in the ISO 105 B02 2014.

Q: What standard do retailers generally specify for towels/swimwear?

A: Every retailer has different requirements, but we would recommend referring to Marks & Spencer as they are a great example for these garments.

Q: Does Pile/Nap surfaces impact the colour fastness to light assessment?

A: It is possible for this to have an impact, try reading Annex E.4.6 & E.8.3 in ISO 105 B02 (2014) for more information.

Q: What is the life of Blue Wool and Xenon Arc Lamp?

A: For blue wools, if properly stored, they can be used for at least two years. Proper storage means unopened in the original packaging in a dry, dark place, protected from direct sunlight and as cool as possible. The environment should be free of chemicals and air pollutants. For the lamps, we refer you to Q&A part one, guidance on when to change lamps can be found here.

Q: Why do you have to use Grade 3 water in light fastness instruments like TruFade, why can't you use normal tap water?

A: Grade 3 water is specified because it has low concentrations of mineral deposits, tap water would contain these which would then deposit inside the instrument and onto the specimens. The water needs to be as pure as possible to keep the machine as clean as possible. Also, the quality of tap water varies from country to country - we talk a lot about controlling variables for accurate and repeatable testing, the water you use is one way of doing this.

Q: With progressing climate change, is it possible that the intensity of the sun light is increasing, due to increased number of sun hours for example, which obviously might vary by location. Are the current light fastness norms still fitting, considering the changing climatic circumstances?

A: It is difficult to disagree with the points raised in the question and there will be many views from experts around the globe, but we feel it is too complex for us to answer this far reaching questions. However, we will put the question to our National Standards Body who will then (hopefully) put the question to the expert panel. Nevertheless, I think they will feel that they cannot progress unilaterally and may seek the involvement of bodies such as ISO and scientific/environmental research organisations to undertake a review of the data and its potential influence on light fastness and weathering testing standards. Obviously the outcome of such studies could have far reaching effects on standards related to textiles and many other industries too. As you can imagine, studies of this nature take years, may be even decades (and may indeed already be in progress or completed), to reach conclusions and formulate predictions which can be used to update future standards.

Q: Is there any alternate to the light source other than the Xenon Arc Lamp?

A: There are two others that we are aware of, Mercury Vapour & Carbon-arc. The TruFade uses Xenon Arc only.

Q: Would atmospheric temperature and humidity affect the testing?

A: The instrument should stay within the set climate settings: Temperate (A1), Dry (A2), Semi-Tropical (A3).

Q: When the specimens need to be tested 3-4 or 5 times (e.g. for VW or Daimler), is it necessary to wait 24h before we measure the blue wool between the cycles? Is the regeneration time minimum 24h or exactly 24h?

A: This is what ISO 105 B02 Clause 9.1 states, so any change from this must be agreed between interested parties. The regeneration time is a minimum of 24 hours.

Q: Can we use aluminium foil as sample masks?

A: You can use any material as long as it is opaque and able to withstand the chamber conditions, however you might need to run some testing to ensure this is the case. We would always recommend purchasing the proper sample masks to ensure your test completes correctly.

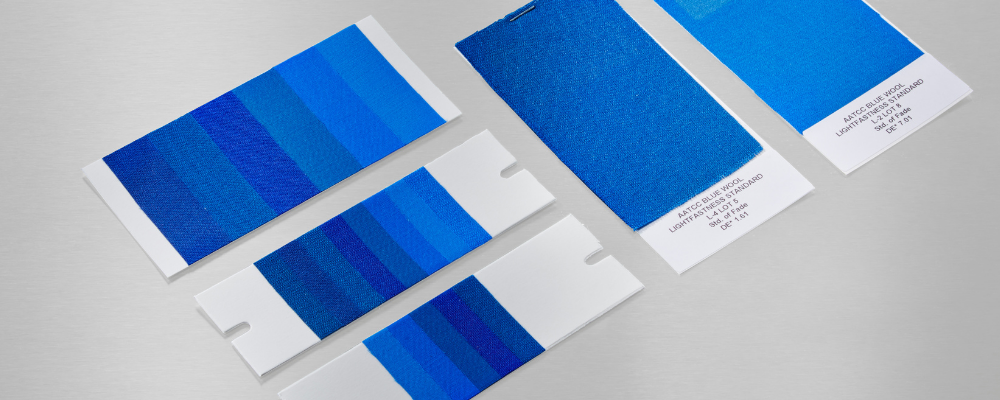

Q: If I test my samples using a Blue-wool card purchased from UK, can I assume I will get a same result of light stability if I test them using a Blue-wool card from the US?

A: No, the ISO and AATCC blue wools are not comparable. To maintain continuity between tests and to be able to confidently compare results, we recommend only using one kind. Below, you can see ISO Blue Wools on the left, and AATCC Blue Wools on the right.

Useful links

If you missed our Light Fastness Testing webinar, you can watch it on-demand.

Part one of our Q&A session is here.

For more information about James Heal's Xenon Arc Tester, TruFade, visit the instrument page.