With a relentless pursuit of quality and innovation in ergonomics and performance for the PPE sector, Latvia’s top university, Riga Technical University (RTU), turned to James Heal to undertake some of the most experimental textile testing their lab has embarked upon in the institution’s 160-year history.

How James Heal innovation took Riga Technical University (RTU) testing to the next level

Established in 1862 in Riga, Latvia, RTU is the oldest of its kind in the Baltic countries, one of the top public universities in the country, and is ranked #751-800 in QS World University Rankings 2023.

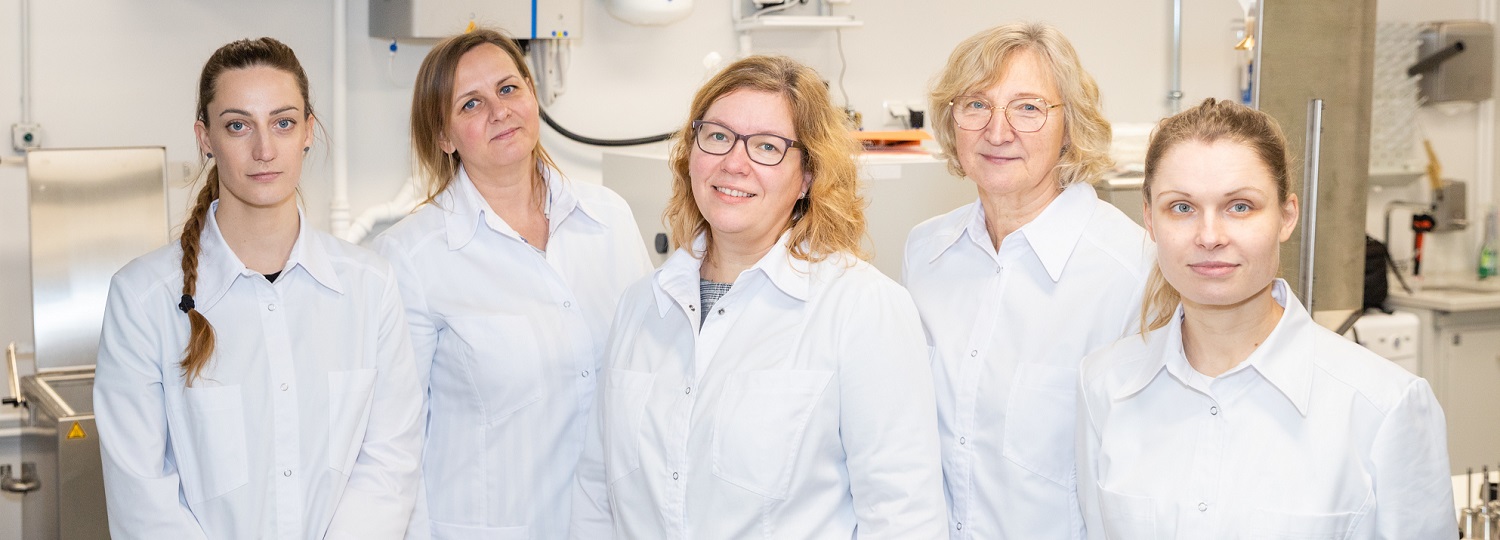

Having worked closely with James Heal for the last year, we took the opportunity to spend time with Professor Dr.sc.ing. Inga Dabolina to discuss performance testing and the importance of ergonomics in textiles and personal protective equipment (PPE). Read the full interview below.

Introduction

Head of Research Laboratories, Professor, and Senior Researcher Dr. Inga Dabolina first came across James Heal’s performance testing instruments at the ITMA 2019 exhibition in Barcelona. After watching a series of product demonstrations, Dr. Dabolina immediately realised that these instruments presented an opportunity for the advancement of the University’s textile testing research.

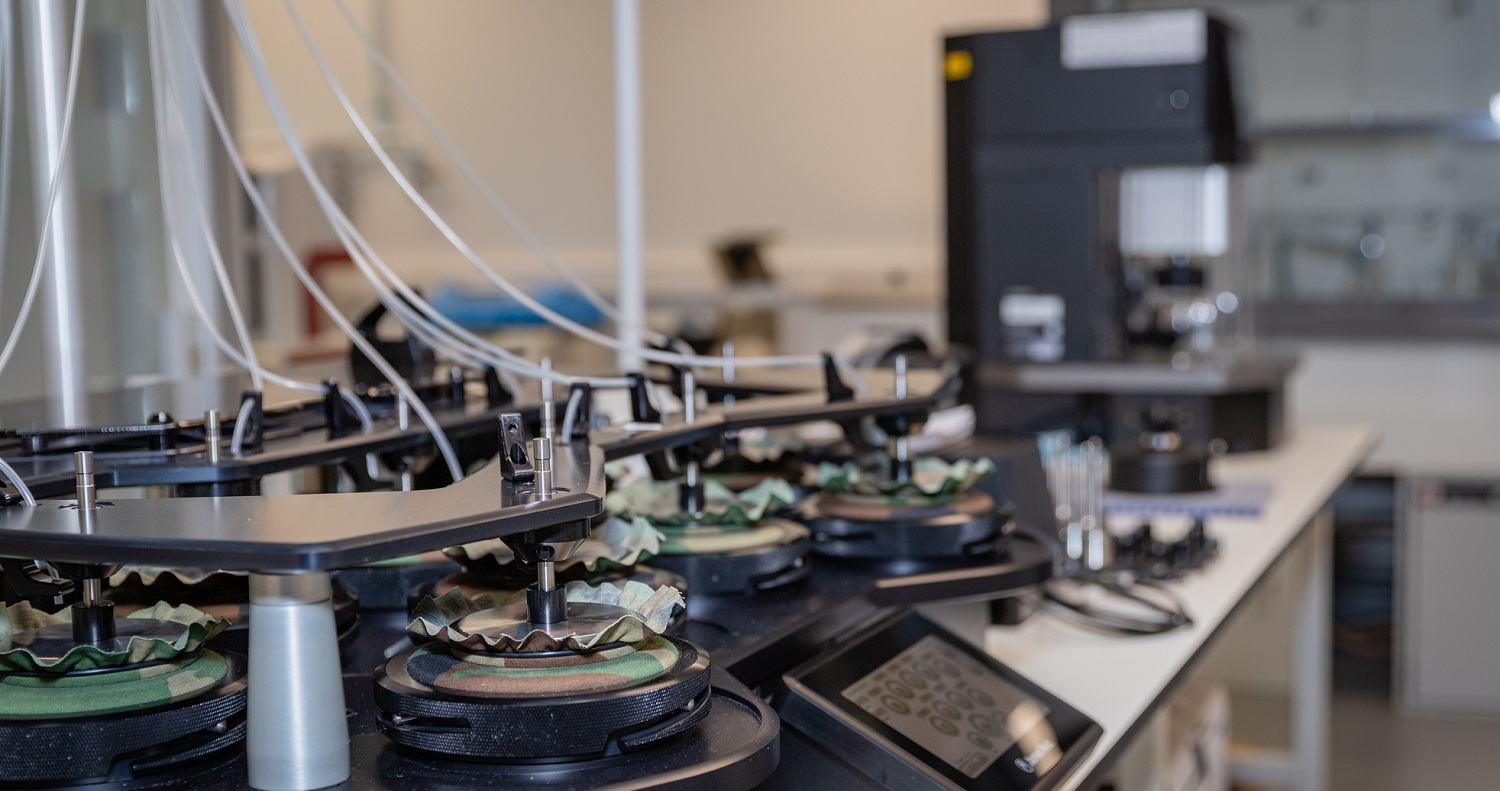

Following the initial meeting at ITMA 2019, Dr. Dabolina was keen to acquire a number of James Heal’s instruments for her laboratory, but at the time wasn’t exactly sure how she would achieve her goal. “It took a while to get the funding needed to equip the lab with the desired instruments. Then, in late 2021 we were finally in a position to acquire a number of James Heal instruments - AquAbrasion, TruRain, TruBurst, FlexiBurn, CrockMaster and Spray Rating Tester - to create a state-of-the-art performance testing environment.”

Finding a solution to an age-old problem

Dr. Dabolina and her team at the RTU research laboratory specialise in the ergonomics and anthropometric fit of clothing and protective workwear - clothing that is worn not by the average person, but by those who work in specific environments such as medical, emergency services, border force, military and all other heavy work conditions.

The anthropometric fit of protective clothing is defined as the correspondence of the garment’s size and shape to the size and shape of the human body. Ergonomics refers to product solutions for human needs – the ability of wearers to perform daily duties and/or tactical tasks, such as work movements or other activities.

A key aspect of clothing for those working in these specialist environments is ensuring protective properties ergonomically enhance the wearer’s safety, says Dr. Dabolina. “Protective clothing must be appropriate to the wearer’s morphology (fit), functional and not affecting the wearer’s capabilities during various routine work movements”.

Dr. Inga Dabolina, Head of Research Laboratories, Professor, and Senior Researcher“If our everyday clothes are too small, big, or uncomfortable, we have the choice not to wear them. Those working in these specialist services do not have such a choice – they have to wear uniforms to perform their duties without endangering their health or life.”

As Head of the Personal Protective Equipment Testing Laboratory at RTU, Dr. Dabolina’s work in the research lab aims to determine the characteristics of anthropometric fit and ergonomics of protective suits and uniforms, to clarify the deficiencies by using objective and subjective study methods and draw conclusions about potential solutions to problems.

“Our customers come to us with specific challenges and use-cases for ensuring the performance of their garments, primarily, complex technical materials used for uniforms and PPE, worn by those whose daily life is related to the use of special-purpose clothing, such as fire and rescue services, the armed forces, national guard, etc. The challenge is being able to replicate real conditions - as the conditions these garments are worn in are often more extreme environments.”

Pictured clockwise: TruBurst, TruRain, CrockMaster and Spray Rating Tester

Moisture: the key to assessing conformity, safety, and comfort

Instruments for more ‘traditional’ textile testing such as abrasion and wear, fire resistance, burst strength and water repellency were covered by the installation of James Heal’s AquAbrasion (Martindale for wet testing), FlexiBurn, TruBurst, TruRain, CrockMaster and Spray Rating Tester.

“I have used Bundesmann water repellency testers in the past,” says Dr. Dabolina, “but the James Heal TruRain has some unique features, such as the re-circulation of water, which improves usability, saves time and significantly reduces water consumption.”

At ITMA 2019, one product in particular that caught Dr. Dabolina’s attention: the AquAbrasion (pictured below). "The traditional tests for abrasion are dated and not easily adapted for the reality of the environments in which they’re worn. Moisture, says Dr. Dabolina, is one of the key areas when assessing the conformity of special protective clothing, and its impact on wearer safety and comfort.

“Our challenge is to objectively evaluate these garments and indicate the shortcomings that need to be eliminated so that the performance of duties is not limited by fit or discomfort. For example, being a firefighter is a very responsible and complicated job, it should not be burdened with an awkward or unsuitable uniform that doesn’t perform as it should.” she emphasises.

Dr. Dabolina was looking for a practical method to assess the abrasion resistance of protective clothing under wet conditions. “When you think about abrasion in relation to protective clothing, in reality, it's mostly worn by people - such as soldiers and firefighters, working under extreme environmental and physical conditions, and frequently likely to be perspiring. We needed a better method of assessing abrasion under wet conditions, and how moisture affects the garment’s performance.”

Working closely with James Heal the team at Riga Technical University has developed a better understanding of how to conduct wet abrasion testing.

Dr. Inga Dabolina, Head of Research Laboratories, Professor, and Senior ResearcherDr. Dabolina’s top tip:

To truly assess a material’s efficacy, says Dr. Dabolina, my favourite test is to get a used uniform and see where the problem areas are and where it shows signs of weakness. “This gives a better understanding of how the product performed in real life, and then we can reverse engineer it to improve performance and also look for potential future problems.”

Final thoughts: Why RTU chose James Heal

When Dr. Dabolina first came across the James Heal exhibition stand at ITMA 2019, she was immediately drawn to the “instruments' distinctive product design and aesthetics”. Intrigued, Dr. Dabolina viewed some product demonstrations being given by James Heal’s technical specialists on the performance instrument range.

“As a scientist, I have to love the equipment I work with. If I don’t enjoy it or trust it, I won’t use it. But seeing the instruments on the James Heal stand at ITMA being demonstrated by their specialists, I could see myself working with the machines, they seemed so easy to operate particularly with the touch screens and integrated software”. After several long discussions, Dr. Dabolina went away “impressed by the machines - but most importantly, the knowledge and attitude of the people at James Heal. I could see they truly had a passion for the product and belief in how it can solve testing challenges for customers”.

Dr. Dabolina (pictured centre below with members of her team) is proud to bring customers and suppliers to the RTU lab, as they are instantly impressed with the all equipment, logistics of the lab and tests, as well as the aesthetic impact of James Heal equipment - which “elevates the impression of our lab as a modern, scientific research facility,” she adds.

Learn more about...

AquAbrasion - wet abrasion testing

FlexiBurn - flammability testing

TruBurst - burst strength testing

TruRain - water repellency testing

Spray Rating Tester – water repellency testing

CrockMaster – colour fastness to rubbing

Take a look at the full range of James Heal textile testing instruments.

Enjoyed this article?

We’ll be sharing more customer stories and insights on our blog - keep checking for updates!