The way clothing interacts with the body, particularly regarding the dissipation of heat and moisture, plays a large role in the wearer’s perceived comfort.

Today, textile fabrics used for clothing have new functional properties to improve the wearer’s sensory comfort and thermal comfort, meaning that air and water vapour permeability to achieve clothing comfort is crucial - particularly for performance apparel such as sportswear and outdoor clothing.

In this application insight, Technical Specialist Peter Goodwin at James Heal, explores the topic of air permeability testing further, looking specifically at the role of comfort in the air permeability of fabrics.

What is air permeability in textiles?

Air permeability is a widely used test which measures how easily air is passed through fabric and helps to indicate the fabric’s breathability, particularly for wind-resistant, weather-resistant and waterproof fabrics.

“Air permeability is defined by the ASTM as the rate of air flow passing perpendicularly through a known area under a prescribed air pressure differential between the two surfaces of a material and is assessed by the volume of air in cubic centimetres (cm3) which is passed through 100cm2 of the fabric in one second at a pressure difference of 10cm head of water.” [1]

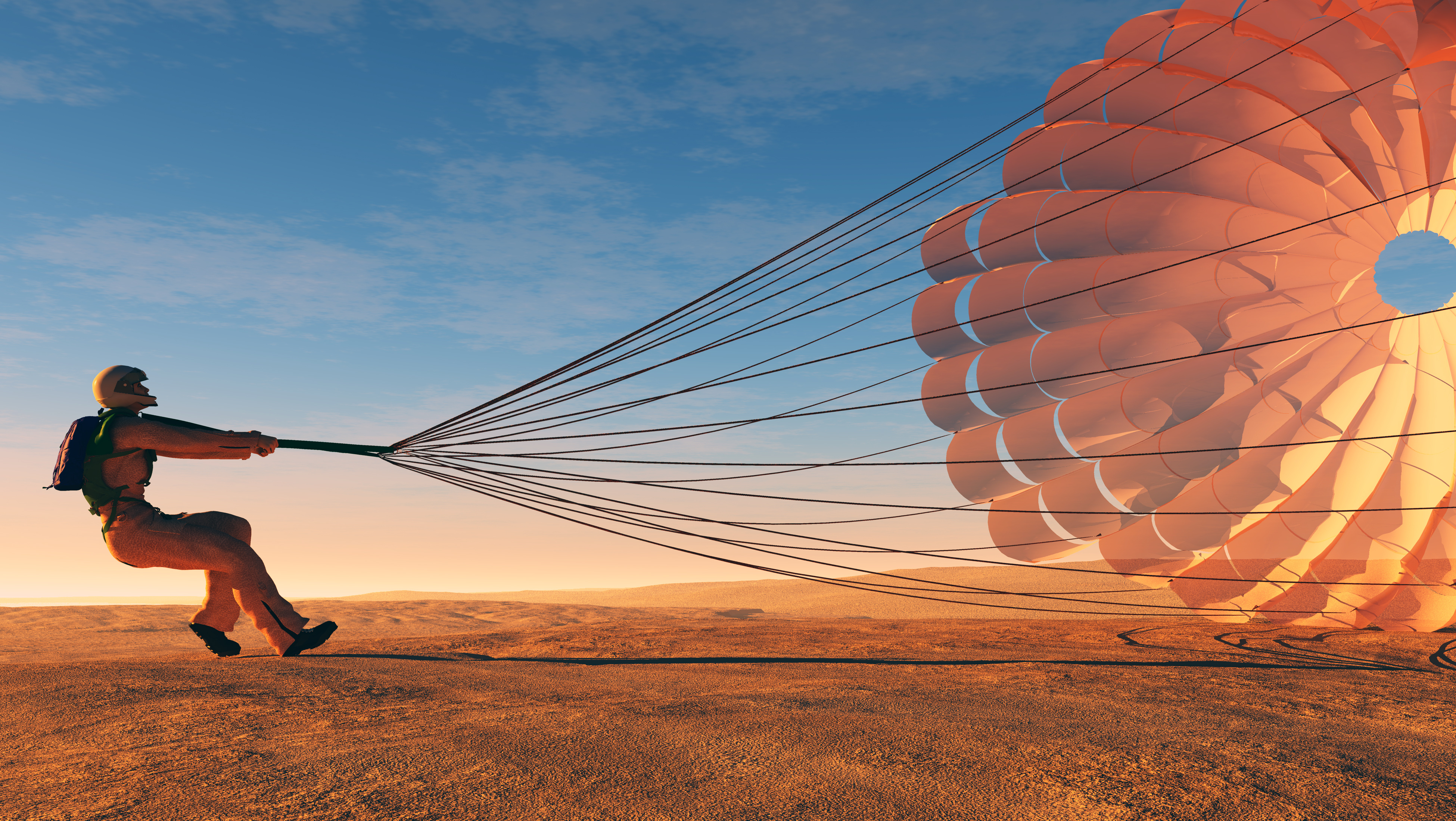

It is an important factor in measuring both the porosity and density of fabric, and assessing the performance of materials like industrial curtains, sails, airbags, and parachutes for a variety of end uses such as military, industrial, medical, automotive and sports/outdoor apparel.

In outdoor clothing, it is especially important for the material’s air permeability to be as low as possible because it should function as protection from wind. Moreover, the performance of nonwoven materials which are used as breathable liners, PPE and filters, is impacted by their permeability to air.

What influences the air permeability of a material?

The main influences on air permeability are the density of the material (shape/value of the fabric/yarn’s pores) and its structure, e.g. the fabric weave, the raw material of the yarns, the set of yarns etc.

In addition, air permeability is influenced by the chemicals and coatings used on the outer layers of clothing, which can modify and/or restrict the flow of air through the material.

- Peter Goodwin"Air permeability can be an indicator of thermal loss in windproof garments, a measure of breathability for face coverings and can prevent infection in medical products."

The role of comfort in air permeability testing

“We can’t discuss air permeability without referencing comfort”, says Peter. “Air permeability can be an indicator of thermal loss in windproof garments, a measure of breathability for face coverings and can prevent infection in medical products. It is a contributing factor to the comfort of a fabric.”

It has been increasingly recognised that comfort testing, which tests the water vapour, liquid moisture transmission and thermal transfer, plays an important role in the development of technical textiles and clothing with a wide range of performance end uses such as professional sports and protective wear.

Many different measurement techniques are being used whose results are not comparable, adds Peter: “Testing for comfort is challenging because ultimately, comfort is subjective to the person wearing the garment.

Air permeability is a suitable test for comfort because the breathability of a material is very important. That includes the flow of air through the garment and its sensorial impact on the skin. For example, items such as raincoats, hiking trousers and tents require low air and water permeability to provide resistance to wind and moisture (water and water vapours), which would impact not only the wearer’s comfort, but also the safety and performance of the garment.”

Air permeability vs breathability: What’s the difference?

"The breathability of a garment is impacted by the material's air permeability, but they are not the same thing", says Peter. “The two terms are often used interchangeably but they have different meanings. The way a material dissipates the wearer’s body heat is breathability. It’s subjective to the person wearing the garment, but if something is ‘breathable’ then heat is dissipated and water vapour (sweat) is prevented from building up - thus providing more perceived wearer ‘comfort’.

“On the other hand, as explained above, how well air can pass through a fabric is not subjective - it’s measurable, and it can be tested with an air permeability test. This is why we recommend using an air permeability tester, such as the James Heal AirPro when looking to assess a material’s breathability and comfort.”

Peter Goodwin, James Heal“Testing on AirPro requires minimal training, so laboratory technicians can quickly use the instrument with confidence.”

Testing for air permeability

The following test methods are used to measure air permeability:

- EN ISO 9237

- ASTM D737

- GB/T 5453

- JIS L 1096:2010 – test 8.26 Method C

- BS 3424-16

- NWSP 70.1

- BS EN ISO 9073-15

How to perform an Air Permeability test

Using a James Heal AirPro air permeability tester, you can conduct an air permeability test following any of the above test methods in just a few simple steps:

Select standard

Select your standard from the pre-loaded standards library, or create your own.

Insert test head and test plate

Insert the test head and test plate size that complies with the specific standard chosen. The software will indicate to the user which test head – or test heads - are permissible for that standard.

Insert sample

Insert the sample into the test area in between the test head and the test plate. Samples don’t usually need to be cut to a specific size for this test.

Clamp sample

Clamp the sample by moving the test arm down, and the test will begin automatically.

Readings

The touchscreen will then indicate when the specimen reading has been found, and AirPro will give an audible alert to let the user know the test is finished. Moving onto the next specimen is quick and easy.

Results

You can read the results on screen, or export them to PDF or Excel. You can create custom reports with fields of your choosing.

More information

For more information on air permeability testing, and performing tests on AirPro, you can visit our product page, or get in touch with us directly.

On-Demand webinars

Take a look at our On-Demand online sessions in the Events section, our 'Introduction to Air Permeability' webinar is a great follow-on resource to this article, and even better, it's completely free.

Contact us today

Get support from the textiles testing experts and talk to us about your test requirements.