Military personnel are exposed to extreme environmental and physical threats, so textiles for military uniforms face a complex set of challenges when it comes to performance: they must offer maximum endurance, comfort, and protection.

Insights into testing military performance textiles

In our performance textiles application insight, technical specialist Peter Goodwin from James Heal explores the growth in demand for testing military textiles, the types of testing required and new innovations in fibre and materials technologies that are pushing the boundaries of function, comfort and performance.

What we'll explore in this testing insight:

- The function and performance challenge for military textiles

- Importance of comfort

- Testing for performance: how is ‘comfort’ evaluated for military textiles?

- Applications for military testing

- Future outlook: Innovation in military textiles

Function and performance challenge for military textiles

"Military uniforms today need to be lightweight, flexible, breathable, moisture absorbing, quick drying, stain resistant, waterproof/water resistant, fire retardant and antimicrobial, in addition to UV ray and body armour level protection" says Peter.

Naturally, this presents a challenge for military fabric producers, where the focus has traditionally been on increasing performance and safety. However, comfort is now more important than ever.

Peter emphasises that both performance and comfort are now both expected of military garments, "In the US in particular, we've seen increased demand for testing, to assess water vapour transmission, drying rate and moisture wicking for these types of materials - along with the more common tests for flammability and colour fastness."

Peter Goodwin - Technical Specialist"Protection, functionality, and identification have long been the primary purposes of military apparel, and ‘wearer comfort’ was less of a consideration."

The role of comfort in military textiles

This, says Peter, is due to the growing demand for the comfort and breathability of the material. This includes the flow of air, water and water vapours through the garment. "A soldier's mobility, stamina and ultimately, survival, are closely linked with the comfort and fit of the gear they’re wearing."

"Textiles that are used in military wear must be able to cope with the most extreme requirements, to ensure product quality, safety and functionality to protect the soldier," he elaborates.

Peter Goodwin - Technical SpecialistTo maintain a uniform heat and moisture transfer, a fabric worn next to the skin should have two important properties: first, evaporate perspiration from the skin; and second, to transfer the evaporated perspiration into the atmosphere.

But what is ‘comfort’ exactly?

"Because comfort relates to how a person ‘feels’ wearing an item of clothing, this makes it highly subjective and thus a difficult area of testing," says Peter. "For our purposes, and indeed the most widely known definition of comfort, it is the way in which a fabric or garment interacts with the body - with regards to how heat and moisture is dissipated. For instance, for a person’s body temperature to remain stable; heat losses need to balance heat production. Therefore heat and moisture transfer for clothing and the comfort/discomfort associated with how hot or cold the wearer feels, is an important consideration, especially for military wear."

Taking inspiration from the area of sports science, various studies have been undertaken, showing that performance of the athlete is improved when wearing clothing that provides good physiological comfort [National Library of Medicine, NCBI]. On the contrary, when a wearer is uncomfortable, this correlates with lower concentration, lower mood and irritability and greater distractions for the wearer, negatively impacting performance.

How is ‘comfort’ tested and evaluated?

The ‘comfort’ of a garment can be evaluated through different types of tests, such as:

- Thermal conductivity / Thermal effusivity

- Flame resistance

- Burst resistance

- Air permeability

- Moisture management/Sweat Wicking

- Wettability/absorption

- Wet abrasion

- Water resistance

- Water repellency

- Drying time/drying rate

In order to provide soldiers with uniforms which best serve their thermo-physiological needs and enhance their perception of comfort, several aspects need to be considered in the design of military garments. For example, the fabric’s heat and moisture transfer processes, moisture management and thermal insulation.

"Essentially, military garments need to be able to optimise heat and moisture regulation; be absent of dampness; have good air and water vapour permeability, along with rapid moisture absorption, breathability and rapid drying," adds Peter.

Allgemeine Ansicht

Der AirPro ist ein konsistenter und präziser Luftdurchlässigkeitsmesser, mit dem Sie die Luftdurchlässigkeit von textilen, gepunkteten und nicht gepunkteten Materialien überprüfen können. Das Gerät ist mit der Software TestWise ausgestattet, die die Bedienung intuitiv und einfach macht.

O AirPro pode ser usado em uma tradução de uma lei de conduta, ou seja, uma lista de materiais, têxteis medicinais, EPI, produtos para bebés, materiais não-têxteis e geotêxteis, um manual de instruções.

Zusammenfassung

Die AquAbrasion ist eine Abrasionsprobe auf der Basis des traditionellen Martindale-Instruments. Es verwendet ein kontrolliertes Bombensystem für die Dosierung der Abriebproben mit Flüssigkeit, die den Abrieb während der gesamten Prüfdauer aufrechterhält. Se puderem utilizar a água desionizada para reproduzir a lírio, ou uma solução de transporte para reproduzir o sudor.

Die AquAbrasion ist eine präzise und wiederholbare Methode zur Durchführung von Abriebtests im Freien, die wir als einen entscheidenden und oft schädlichen Schritt zur Feststellung der Haltbarkeit von Außenwänden erachtet haben.

Allgemeine Ansicht

WickView ist ein Gerät der neuesten Generation, das ein modernes Bildsystem zur Messung und Registrierung des Feuchtigkeitsgehalts von Textilien und anderen Materialien verwendet.

O Feuchtigkeitsmesser WickView é um site de Textos de Textos de Texto, que é o primeiro material a ser publicado no Feuchtigkeitsmesser WickView na Realität Berlin.

Allgemeine Ansicht

Der HydroView wird zur Bestimmung der Wasserbeständigkeit von Textilien verwendet und ist ein hochpräziser und konsistenter Wasserdichtigkeitsprüfer von James Heal.

O HydroView pode ser usado para a impressão de textos próprios, como, por exemplo, na Alemanha, no Reino Unido, nos Países Baixos, nos Países Baixos, nos Países Mediterrânicos, nos Países Baixos, nos Países Baixos, nos Países Baixos, nos Países Baixos, nos Países Baixos e nos Países Baixos.

Zusammenfassung

Die schnelle Abkühlung ist eine wichtige Eigenschaft von Textilien, die während sportlicher Aktivitäten, bei denen die Haut transpirieren kann, zusammen mit der Haut getragen werden. Ohne diese Eigenschaft kann die Feuchtigkeit nicht so leicht aus der Haut verdunsten, was dazu führen kann, dass der Benutzer sich unwohl fühlt. ProDry reproduziert die Einsatzbedingungen, um zu überprüfen, ob die Schnellwaschmittel effizient abtrocknen.

Zusammenfassung

TruRain ist der endgültige Bundesmann-Test, ein künstliches Wasserprüfgerät zur Bestimmung der Wasserabweisung von Textilien. A partir do momento em que o Berücksichtigung der Genauigkeit se tornou uma das mais importantes inovações e o Genauigkeit und Wiederholbarkeit der Ergebnisse zu verbessern.

TruRain führt Prüfungen nach der Norm ISO 9865 - Determinación de la repelencia al agua de los tejidos mediante la prueba de lluvia artificial Bundesmann durch.

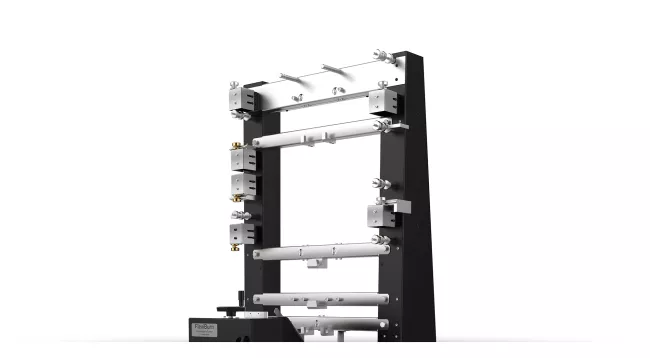

Performance textiles testing range

The James Heal performance textiles testing range of instruments has been developed for testing the complex requirements of technical and performance textiles used in the military.

Applications for military textiles

The fabrics and end uses for military textiles are broad and diverse. From parachutes and tents, to backpacks, bullet-proof vests and full body armour; the materials used to produce military apparel are specially-developed technical yarns which are used to support, strengthen and enhance the product/garment to perform under pressure.

In addition to those mentioned above, other applications for military textiles include:

- Utility belts, hats and gloves

- Ponchos

- PPE and masks

- Rocket linings

- Straps, cords, cables and ropes

- Helmet covers

- Bedding/mattresses and blankets

Future outlook

Developments are being made to monitor and maintain records of physiological activities and vital signs using smart textiles in military garments. These innovations in smart textiles technology for military applications are designed with the wellbeing of the wearer in mind, bridging important gaps between military textiles, and other areas such as medical textiles.

"The military textiles space is undergoing significant innovation."

"In future, we expect to see further transformation of traditional fibres, yarns and textiles into highly sophisticated ‘smart textiles’, with integrated devices and systems such as nanotechnology and skin-like camouflage, enabling automated detection of the environment or threat which will adjust functionality and/or protection level to adapt to external changes."

Contact us today

Get support from the textiles testing experts and talk to us about your test requirements.

Enjoyed this article?

Keep checking for more new customer stories and insights on our blog.