W. L. Gore the inventor of GORE-TEX has worked with James Heal for many years. In this case study we learn how their R&D Lab teamed up with James Heal to tackle their sustainability challenges.

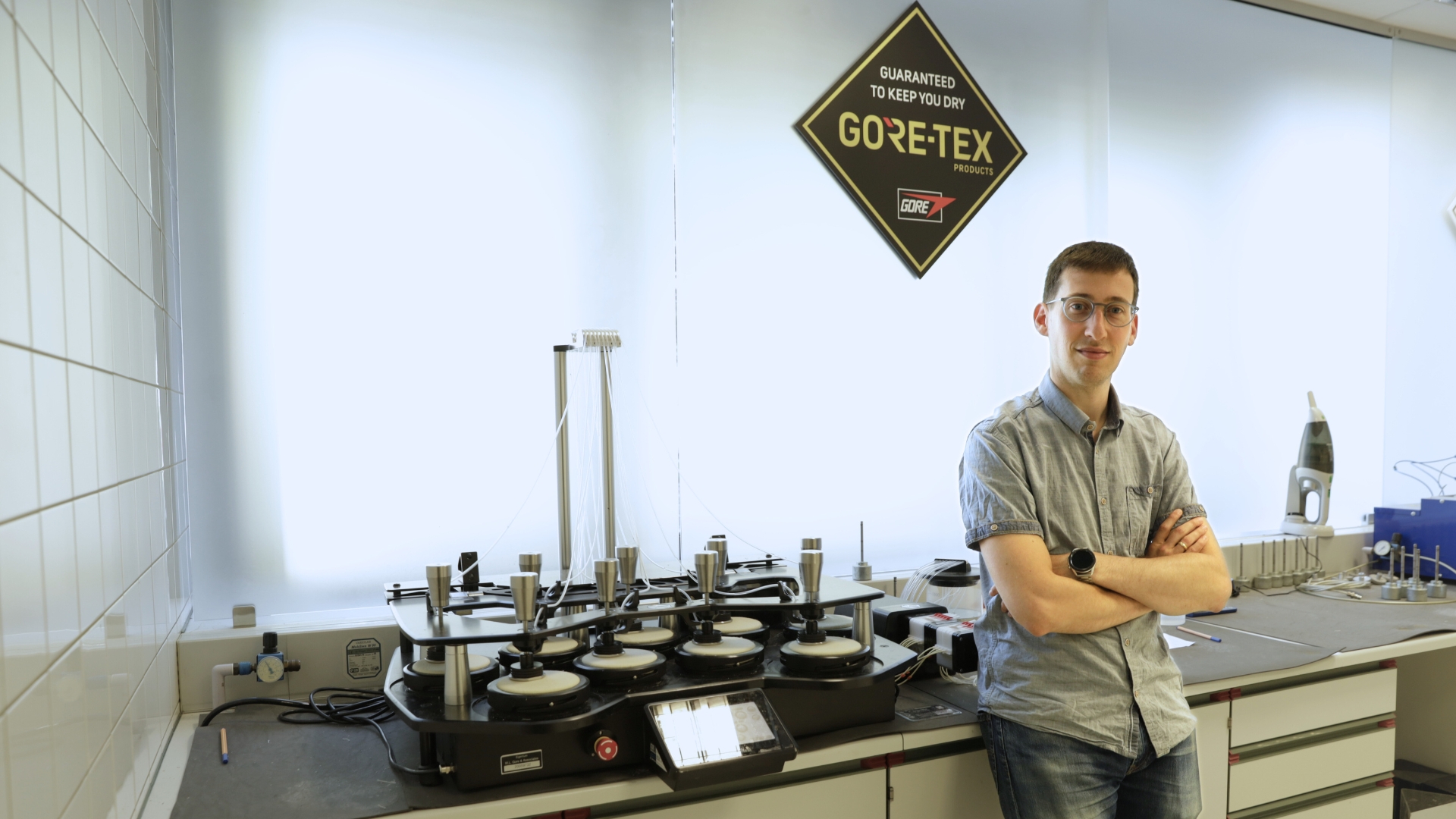

On the second anniversary of Lab Leader Rodrigo Arredondo’s employment with W. L. Gore & Associates GmbH, we talked about his role and the testing undertaken in the lab he manages in Feldkirchen-Westerham near Munich in Germany, and crucially the work involved in achieving the company’s sustainability goals.

The Company: W. L. Gore

Best known as the inventor of GORE-TEX, a durable waterproof, windproof and breathable membrane system that is widely used in high-end outdoor garments, footwear and gloves, W. L. Gore (Gore) is a global materials science company dedicated to transforming industries and improving lives.

“Our laboratory performs R&D textile testing for the development of new GORE-TEX laminates for footwear and gloves inserts. I’m responsible for the lab team, lab safety and maintenance, as well as managing lab capacity.” Rodrigo explains.

With a background in mechanical engineering, materials science and nuclear fusion, Rodrigo has a very interesting career background. Looking for his next challenge and the opportunity to learn something new, the Gore proposition interested him enough to make the move into the textiles industry.

Types of testing undertaken in the lab

Being focused on R&D, the Feldkirchen lab team are tasked with performing a broad range of textile tests, in varying conditions. Testing is undertaken on consumer products including outdoor footwear and running shoes, as well as safety and workwear items to be used for example, in medical or emergency services settings such as fire and rescue.

These include Suter testing for waterproofness, colorfastness under various conditions, spray rate testing, vertical wicking, air permeability, moisture vapour transmission rate, Martindale abrasion, tensile and peel tests, and washing testing to simulate use via artificial aging.

Rodrigo Arredondo, Lab Leader at W. L. GoreWith our James Heal instruments, we have reliable testing tools that give us confidence in our lab results.

How Gore is addressing the challenges of sustainability in textiles

“Gore takes R&D very seriously.” Lab Leader Rodrigo says, “Over the past few years, we have observed the outdoor industry collectively moving away from PFAS-based materials and surface treatments, and have worked hard to develop a new line of expanded Polyethylene-based (ePE) laminates.” he continues.

Gore is committed to making this change and is fully transitioning their entire commercial laminate portfolio to ePE and PFAS-free DWRs (Durable Water Repellents) while maintaining their high standards for durable waterproof, windproof, and breathable materials. In doing so Gore has made significant gains on their sustainability journey, also strongly reducing their environmental footprint during the entire product lifecycle.

“It takes around four years for a live product to come to fruition in a project such as this. Our aim is for all our consumer-oriented portfolio to be PFAS-free by the SS26 season. Safety and defence laminates will follow by 2031at the latest, hopefully sooner.” adds Rodrigo.

Some aspects of the development of PFAS-free textiles are more challenging than others, with speciality laminates such as for fabrics with anti-viral properties, or in protective wear products that require additional protection in certain applications such as oil repellency.

Pursuit of the PFAS-free goal involves using natural based products, that contribute further to the company’s sustainability goals, by using less water and energy, with the ability to recycle products post-use.

Advantages of textiles testing with James Heal instruments

The R&D lab has two James Heal DynaWash instruments which have been used since 2017. More recently Gore added two James Heal AquAbrasion wet abrasion testers to broaden the lab’s capabilities.

“We’re very happy with our James Heal instruments. They’re easy to use and we always get good support quickly whenever we encounter any issue.” says Rodrigo.

With the high-end reputation of Gore products, it is expected that they will last well and still look good over time, even through use in harsh outdoor conditions, so testing durability in varying conditions and also using aggressive laundering is key to quality assurance.

The lab uses DynaWash to test durability of products, as well as to help gauge delamination and shrinkage, in an accelerated washing cycle that replicates the impact of repeated domestic washing in a single cycle, creating efficiencies compared to other washing machines, which the team also utilise. Reducing the number of washes needed for testing means savings in energy and water, as well as time.

Meanwhile the AquAbrasion is used in particular for wet testing abrasion and pilling, alongside other Martindales used for wet and dry abrasion testing. Depending on the test this can be half a million or even up to a million cycles.

“A unique selling point of the AquAbrasion was the automatic water dosage system, coupled with competitive prices for a machine with 9 positions. When we decided to purchase them, we already had experience with James Heal through our DynaWash instruments and were happy with the service provided.” says Rodrigo of the experience working with James Heal.

“We are very happy with our AquAbrasion instruments, in contrast to having sometimes encountered issues with our other brand Martindales which required unplanned maintenance and repair.” he adds.

Several years prior, Gore worked with the James Heal Innovation and Technical teams on the original project to help them to develop the AquAbrasion concept and subsequent test method.

Rodrigo Arredondo, Lab Leader at W. L. GoreI would recommend James Heal instruments to other laboratories. We’re very happy with the level of service we receive from the PPT Group team in Germany.

Rodrigo’s opinion on features of the James Heal instruments in the lab?

“With our James Heal instruments, we have reliable testing tools that give us confidence in our lab results. One feature I particularly like is the automatic water dosage system of the AquAbrasion, as this makes wet abrasion testing easier and minimises potential for human error.

In addition to the test instruments, we also order Martindale abrasion test materials from James Heal and rely on their Service and Calibration annually to ensure accuracy, reliability are maintained.”

Final thoughts on the working relationship with James Heal…

“I would recommend James Heal instruments to other laboratories. We’re very happy with the level of service we receive from the PPT Group team in Germany. A big thank you to them for their continued support!” concludes Rodrigo.

Head of Sales for James Heal in Germany, Lutz Gerold added, “It is a pleasure to work with Rodrigo and his team in the W. L. Gore R&D lab. We have an excellent working relationship and together we can address the challenges of this fast-evolving industry.”

Want to learn more?

For further explanation on the benefits of longevity testing, take a look at our article Product focus: DynaWash durability tester and the Expert Q&A: Durability testing in the age of fast fashion and diverse performance with our Technical Specialist Peter Goodwin.

Read our Essentials article, AquAbrasion: Assessing the true impact of the outdoors on outdoor wear and download the AquAbrasion eBook for further insights into this fascinating area of abrasion and wear testing. In addition, we have an on-demand webinar Performance Testing: Wet abrasion that will also provide useful information on wet Martindale testing.